Energy Efficiency in RAS: Strategies to Reduce Operational Costs in Canadian Aquaculture

Operating land-based Recirculating Aquaculture Systems (RAS) in Canada’s cold climate presents unique financial challenges, particularly due to higher energy demands for water circulation, filtration, and heating. Unlike traditional pond-based or net pen systems, where nature assists temperature control, RAS must actively manage environmental conditions year-round, especially during harsh winters.

Why Energy Costs Matter in RAS

Energy is widely acknowledged as a major operational cost driver in RAS, second only to feed expenses. Energy use in RAS is high and varies based on system design, species cultured, and the climate where the facility operates. (WAS)

While precise percentages vary significantly between facilities, independent industry data show that RAS energy demands are inherently higher than many traditional aquaculture systems, due to continuous life-support technology and water treatment requirements. (ScienceDirect)

Because of this variability, energy efficiency measures are critical — especially in cold climates where heating demands increase overall energy usage.

1. Reduce Heat Demand with Better Insulation & Heat Recovery

In cold climates, a significant portion of RAS energy use is devoted to heating water and maintaining stable temperatures.

Engineering analyses demonstrate that:

- RAS heating demand is higher than flow-through systems — often 1.4–1.8× more energy on a life cycle basis. (ScienceDirect)

- Integrating heat recovery systems can reduce annual heat consumption by over 50% compared with systems without heat recovery, depending on heat exchanger efficiency and building insulation. (ScienceDirect)

How it works: Warm effluent water is passed through a heat exchanger where its thermal energy is transferred to incoming fresh water, reducing the load on primary heating systems. This contributes to reduced fuel/electricity use and lower utility costs. (ScienceDirect)

Tip for Canada: Combining heat recovery with high-performance insulation in walls, roofs, and piping will yield the greatest heating cost reductions.

2. Optimize Pump and Filtration Systems

Pumping and filtration are necessary for maintaining water quality, but these systems can add significantly to energy costs if not optimized.

Independent technical studies show that:

- Pumping and mechanical systems account for a significant share of total energy use — though the exact proportion varies widely by facility and design. (ScienceDirect)

RAS designers and operators frequently use Variable Frequency Drives (VFDs), which allow pumps to run at speeds matched to actual flow requirements throughout the production cycle.

Benefits of VFDs:

- Reduced pumping energy.

- Lower peak electrical demand.

- Better matching of recirculation needs with actual biological load.

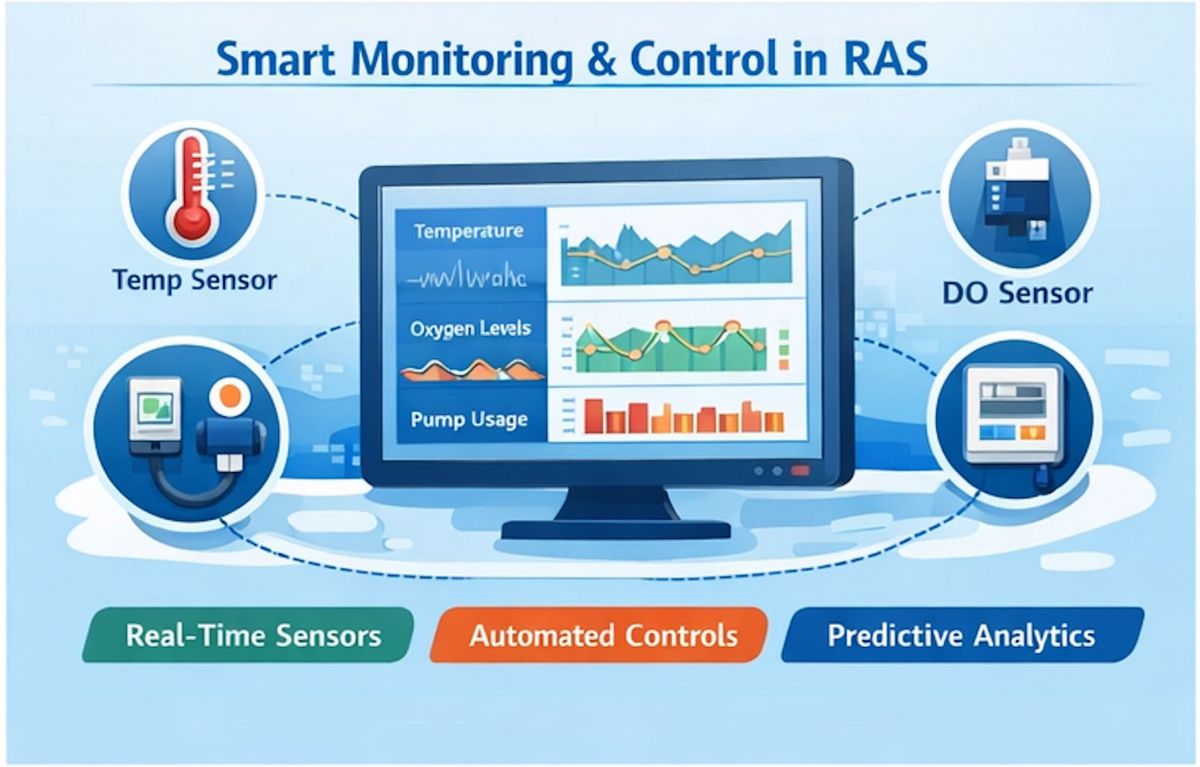

3. Smart Sensor Networks & Predictive Controls

Modern “smart aquaculture” technologies apply sensors and data analytics to manage energy use more efficiently.

Key advantages include:

- Real-time monitoring of water temperature, dissolved oxygen, and flow.

- Automated adjustments that prevent over-aeration or unnecessary heating.

- Predictive algorithms that anticipate energy needs based on fish growth stages and environmental conditions.

This approach not only reduces energy waste but also enhances animal welfare and production stability.

Conclusion:

Energy cost reduction in Recirculating Aquaculture Systems is essential — not just for sustainability, but for economic viability in cold climates like Canada’s. Strategies such as heat recovery, optimized pumping systems with VFDs, and smart energy controls grounded in real-time data can turn energy from a cost liability into a strategic operational advantage.